Super Steel is your ultimate fabrication partner. From defining exact requirements to Design-for-Manufacture ideas to the delivery of quality, conforming product to your destination. Super Steel is a proven expert in providing steel welding, engineering, complex fabrication, complex assembly, and painting of parts and products. From breadbox-sized items, literally up to locomotives; Super Steel continues to win client partners via our innovative management and processes, and our basic blocking and tackling of day-to-day personal execution on our promises to you. Explore our capabilities below. Click the links to jump directly to the topic.

A critical priority for Super Steel and a priority for its customers is realizing an environment where employees can work safely. This commitment reflects Super Steel’s legacy and its continuing pledge to meet the needs of our team, business partners, and the communities in which we live and work.

CAPABILITIES:

- New Product Introduction (NPI)

- First Articles (FAI)

- Production Part Approval Process (PPAP, all levels)

- Engineering support, design for Manufacturing (DFM, PFMEA)

- Simple through Complex Metal Fabrication

- Simple through Complex Assembly and Test

- Power and Liquid Painting (large format capabilities)

- Welding (following AWS, with CWI oversight, Carbon Steel, Alloy Steels, Aluminum and Stainless Steel)

- And many more!

NEW PRODUCT INTRODUCTION

![]()

Once the decision is made that a supplier change is in order, the next concern for the procurement professional is the transition. Will the new supplier deliver a quality product on time? Super Steel has developed a specific process and has dedicated a team of manufacturing professionals to address this concern. We call it New Product Introduction. Attention to detail, constant communication, and the desire to execute the plan are what make the New Product Introduction process a success.

So, what is a New Product Introduction plan? We’ve created a plan to evaluate how a product will be made and ensure things go smoothly. With every new product we introduce, we check 100% of the parts and process before it ever sees the production line. We decide on and implement extensive engineering, planning, and quality checklists to ensure the success of every product we manufacture. From the kick-off meeting to the multiple reviews and evaluation, we make sure we can get it right every time. When we find issues, we make sure to correct them on the front end. This way, we run into them less later.

As part of our ISO registration, we make sure we can deliver on our promises. This is one way of many to do just that.

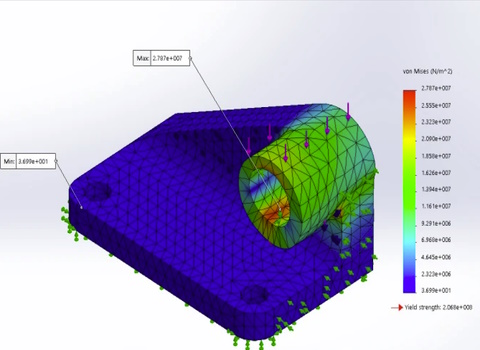

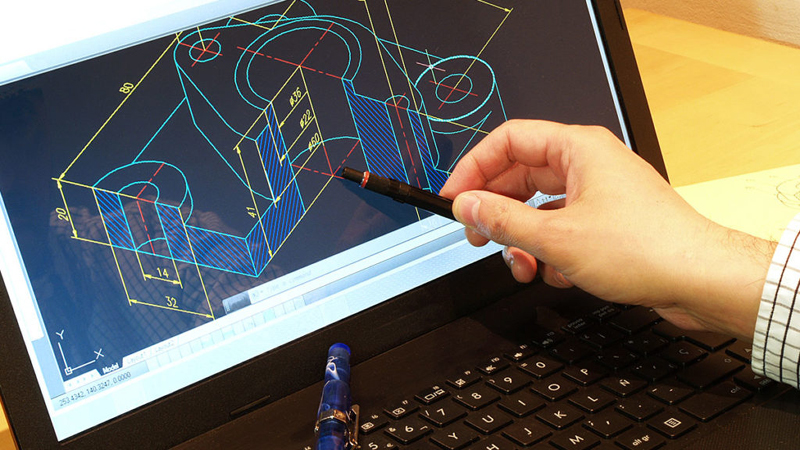

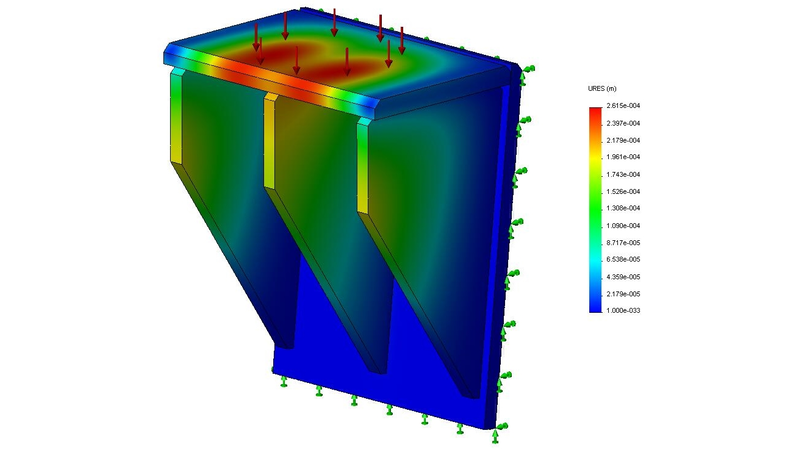

ENGINEERING

Our expert staff includes degreed mechanical design engineers, experienced tool and fixturing designers, process manufacturing engineers, 3D modeling, Finite Element Analysis (FEA), CAD – CAM, and certified welding technicians. Altogether, our customers receive the confidence that more than 300 years of engineering and manufacturing experience provides. As a result, whatever your product and needs, our engineering team creates manufacturing solutions to ensure production runs smoothly, repeatedly, at the lowest total cost of ownership (TCO) to get a better, high-performance quality product to our customers on time.

ENGINEERING INNOVATION

At Super Steel, we believe our ‘solutioneering’ process connects us with our customers to bring about new ideas, methods, products, services, or solutions that have a significant positive impact and value.

- We think “outside the box” for various applications and solutions:

- Complexity – innovations can show up in large complex assemblies

- Simplicity – innovations can show up in the simplest of parts

- Artistic – innovations can be non-typical, outside the heavy industrial business

- Process – everything follows a prescribed, clear, and systematic process to ensure the finished product meets expectations

CAD / CAM 3-D MODELING ENGINEERING SOFTWARE

- Solidworks 2020

- Boost with Osean

- Fuson 360

VALUE-ADDED ASSEMBLY

- In the event that you need assistance, we aid in the customer design process to support a wide range of assembly types:

- BOM’s as simple as 2 parts

- BOM’s as complex as 4000 parts

- Sub-assembly testing and qualifications

- Specification and procurement for:

- hydraulics

- electronics

- electromechanical systems

- Paint and corrosion-resistant finishes to metal fabrications

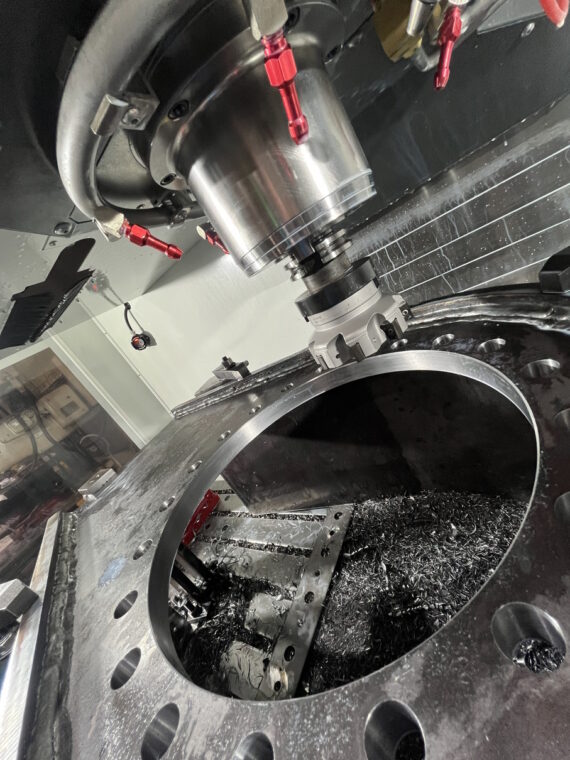

CNC MACHINING

- High-precision and versatile G&L (Boring Bar) and HAAS (VMC) machining centers ensure quality and productivity standards are met. Known for their capabilities, reliability, and durability, it allows us to provide custom designs and quick turnaround of unique components our customers require.

FABRICATION

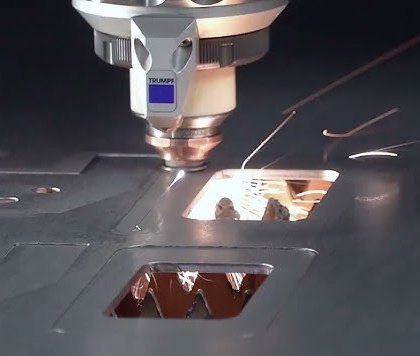

- Laser cutting solutions

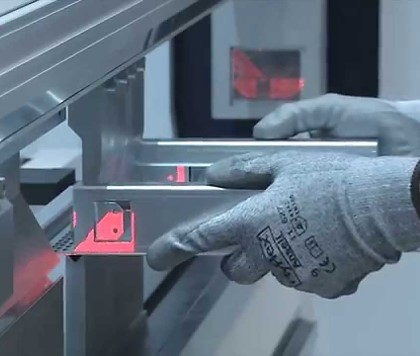

- Metal forming technologies

- Use and fabrication of high strength materials

- Full welding, weld testing, and certification

COMPLEX FABRICATION

As a provider of complete manufacturing solutions, we use the broadest possible range of metals and welding technologies for the most complex metal fabrication. This experience means we can handle products that require more than one process to be fabricated. There is no need to switch providers as specifications change.

METAL FABRICATION EQUIPMENT

- Amada CO2 Laser – up to 4,000 watt with 5’ x 10’ table

- Trumpf 5040 Fiber Laser – 12,000 watt with 6’ x 12’ table

- Trumpf, Cincinnati and Chicago CNC Press Brakes (6) – 90ton (88”) through 1000ton (22’)

- Messer High Definition Plasma Cutting Machine (1) – 12’ W x 45’L table, 1 x 400XD with Truehole Technology (3.2” cutting capacity, 2” clean cutting capability), 4 x Oxyfuel Torches (16” cutting capacity) with Infinity Rotator

CARBON STEEL

Successful carbon steel welding requires a craftsman’s knowledge of the way each alloy responds. Super Steel’s AWS-certified craftsmen, aided by engineering professionals, create carbon steel weld sequences that maintain precise conformity to a customer’s design parameters.

STAINLESS STEEL

Successful stainless steel welding demands detailed knowledge of the material’s unique response. Through careful design of weld sequences, Super Steel craftsmen and Engineers create stainless steel welds to meet the strength and dimensional needs of an original design.

ALUMINUM

Aluminum welding demands special expertise. Super Steel uses years of aluminum welding expertise to safely create products with superior strength and exact conformity to the original design.

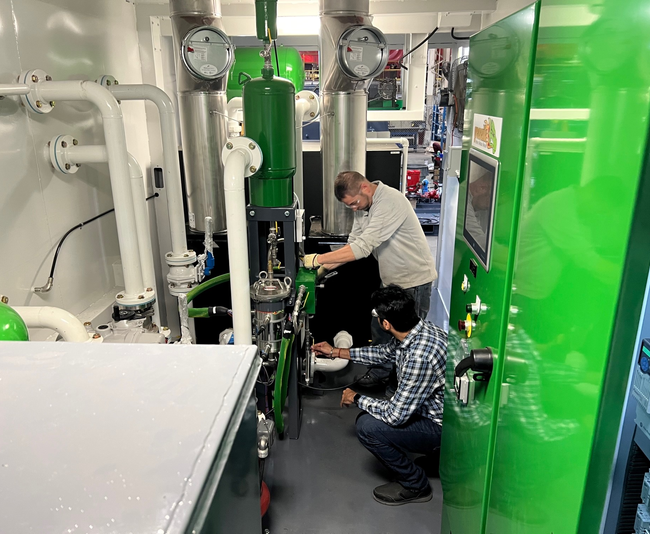

COMPLEX ASSEMBLY

Excellence in complex assembly manufacturing is a key reason customers trust Super Steel as a provider of Complete Manufacturing Solutions. This means the same rigorous attention we give to process control applies to all assembly jobs. As a result, from the simplest nut-and-bolt work to the creation of complex electrical and computerized controls, we have the attention to detail to make sure it’s done right.

COMPLEX ELECTROMECHANICAL ASSEMBLY

- Complete product assembly for POU’s at your floor

- Pneumatic assembly

- Hydraulic assembly

- Component assembly

- Electrical schematic assembly

- Hipot testing to ensure quality

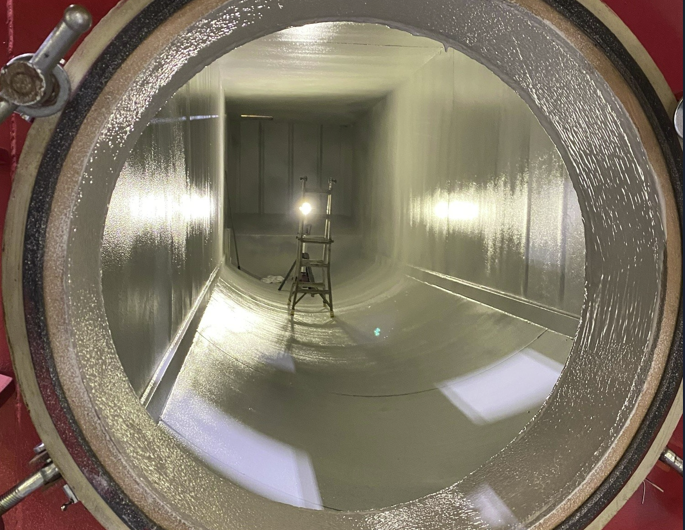

PAINTING

Super Steel’s large-format paint booths offer expert capabilities with a variety of painting options, including liquid and powder. Strict processes that meet or exceed customer specifications are in place for painting everything from small metal parts and components to assemblies the size of complete locomotives, all with a uniform commitment to quality.

PAINT BOOTH CAPABILITIES

- Liquid Spray – Batch

- 20’W x 15’H x 80’L

- 20’W x 15’H x 25’L

- 12’W x 15’H x 24’L

- Powder Coat – Batch

- 12’W x 12’H x 20’L

- Color matching capabilities

BLAST BOOTH

- Shot Blast (medium & fine)

- 15’W x 13’H x 54’L

- 12.5’W x 11’H x 14.5’L

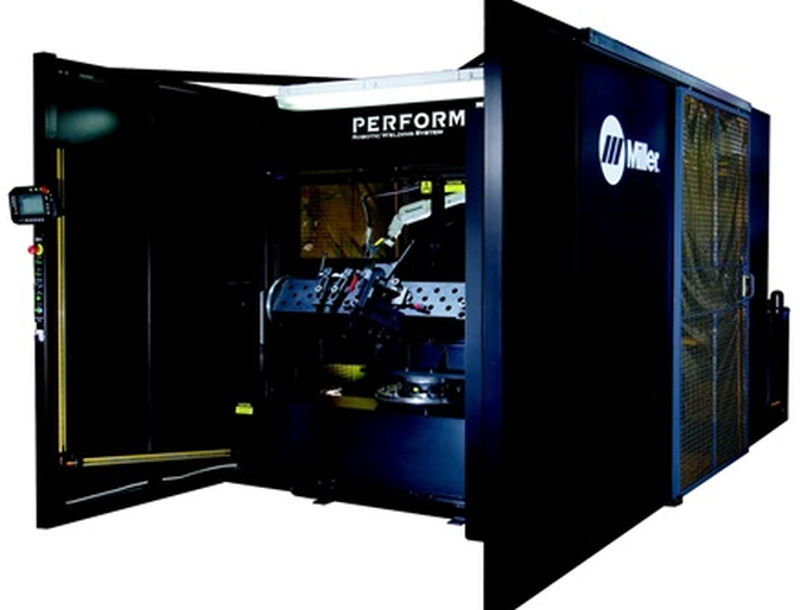

WELDING

With our broad range of equipment, AWS certified welders, weld school, and talented welders on staff, we’re here to get your project done.

WELDING EQUIPMENT

- Weld Machines – MIG, TIG, Flux-Core, and Stick Welding

- GMAW Short Circuit

- GMAW Pulse

- Spot Welders – Up To 150 KVA

- Stud Welding Machines – Capacity To 1/2 Studs

- Bluco Modular Weld Tables and Fixtures

- Robotic Welders:

- Miller Electric PA 1100 HW Performarc Robotic Welding System, Twin Station, 60″ L x 40″ Wide

- AGT Robotics, BLOK 500 Series, Single/Dual Zone, 9 Axis Welding, 112′ X-Axis, 13′ Y Axis, 6′ Z-Axis SnapCam3D, 24,000lb Head/Tail Stock Positioners

Super Steel has the on-site presence of AWS certified welders in our Milwaukee production facility, weld instructors, and weld inspectors. Our team is ready to take your project from prototype to product and deliver quality every step of the way. This means assured quality on all of the weld types Super Steel provides:

- On-Staff Certified Weld Inspectors

MIG | TIG | Flux Core | Sub Arc | Brazing | MilSpec | Robotic

Process | Material Capabilities |

| MIG – GMAW Flux Core – FCAW Submerged Arc – SAW TIG – GTAW Spot Welding – RSW Stud Weld – SW | Carbon Steel Alloy Steel Aluminum Stainless Steel |

Qualified Weld Procedures | Testing & Training |

| American Welding Society – AWS American Society of Mechanical Engineers – ASME Military Standard – MIL-STD European Committee for Standardization – EN German Institute of Standardization – DIN | Classroom & Hands-On Training Facilities Welder Qualification Testing Continuing Education Program Weld Procedure Testing |