Through the ongoing efforts of a three-year multimillion-dollar reinvestment plan, Super Steel is systematically upgrading and replacing machinery with state-of-the-art equipment and technology that dramatically improves reliability, capabilities, capacity, and quality.

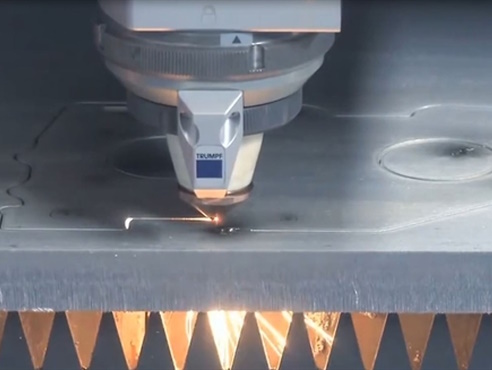

The most recent examples are the additions of the Trumpf laser, forming, and processing technology. A 2D Tru Laser 5040, 12K fiber, solid-state, 6 x 12 laser and Tru Bend 5320, 390 ton, 174” press-brake, both with a wide range of options enabling consistent, repeatable, high-precision quality cutting and bending that are tied to Trumpf’s industry-leading Osean and Boost process technology. By leveraging Trumpf to cover processes from part identification to consistent, high-quality finished parts gives Super Steel a clear competitive advantage and makes cutting and bending parts for our team easier, reducing errors while also making these operations safer.