Total Customer Satisfaction and Continuous Improvement is Everything We Do.

Super Steel is committed to meeting our customers’ quality, delivery, and value expectations. We develop, maintain, and continuously improve our quality management system and place its principles at the very center of everything we do. Our Continuous Improvement Programs investigate more effective ways to improve processes to ensure repeatable quality. We strive to realize our 6Rs that ensure our business partners receive the Right product at the Right time, in the Right place, with the Right quality, in the Right quantity, and at the Right cost.

QUALITY STANDARDS & CERTIFICATIONS

- ISO 9001:2015 Registered

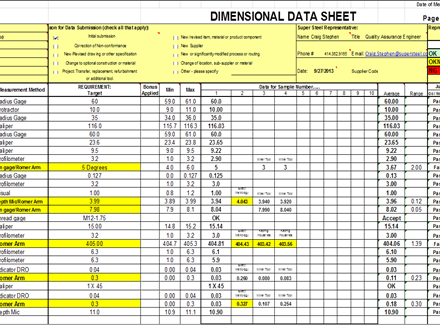

- 6′ HEXEGON CMM 7 Axis Inspection Arm (with Laser Scanning)

- Welders are tested and qualified to AWS codes; D1.1, D1.2, D1.3, D1.6

- CWI Certified AWS Welding Inspectors

- SolidWorks™ 2020 3D Interface prep for ISIR

- Process Failure Modes & Effects Analysis (PFMEA)

- Advanced Product Quality Planning (APQP)

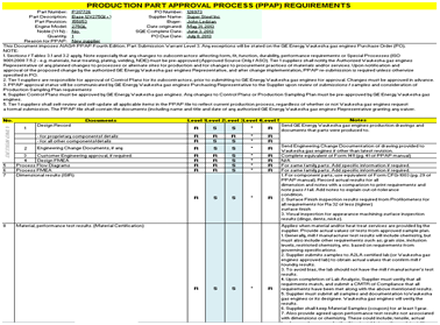

- Production Part Approval Process (PPAP)

- First Article Inspection (FAI)

- Carboline paint certification

- 6 Sigma Lean Yellow/Green/Black-Belt certified team leaders

ISO REGISTRATION CERTIFICATE

ADVANCED QUALITY ASSURANCE PLANNING

- Identify Critical-to-Quality Features

- Identify Inspection Method and Tools

- Review Tooling Plan

- Create Quality Checklist

PPAP – FAI INSPECTION PLANS

- Provide FAI, ISIR, PPAP Documentation Based on Customer Specific Specifications and Recommendations

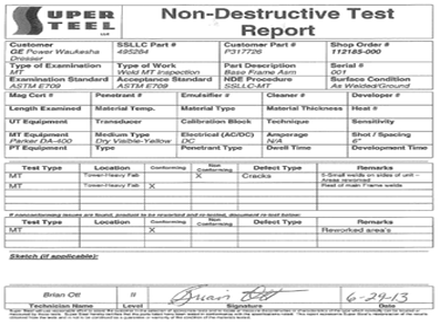

- Functional Testing, NDT Weld Testing and Material Certifications Available

- Used for New Products, Design Changes or Annual Submissions

- Planning

- Determine our “Supplier Quality” Contact

- Track QA Responsibilities

PROCESS FMEA

- Process FMEA Capabilities Through the Use of Cross-Functional Teams

- Result Outputs Used to Develop Inspection Control Plans

WELDER TESTING AND CERTIFICATION

- On-site Procedure Qualification and Weld Process Specification

- AWS Certified Welding Qualifications (WPS)

- Traceability Through Welder Database

- Certified Welding Inspectors on Staff

- Certified Lean Yellow, Green and Black Belts

- Level II NDT Technician On Staff (UT, MT, PT)

- ISO 2253 Weld Symbols and Joint Design

- Ability To Qualify And Test To Customer Specific Requirements